Electromobility

The automotive industry is undergoing a worldwide transformation – the combustion engine seems to have reached its zenith. Today, electric vehicles are on the rise.

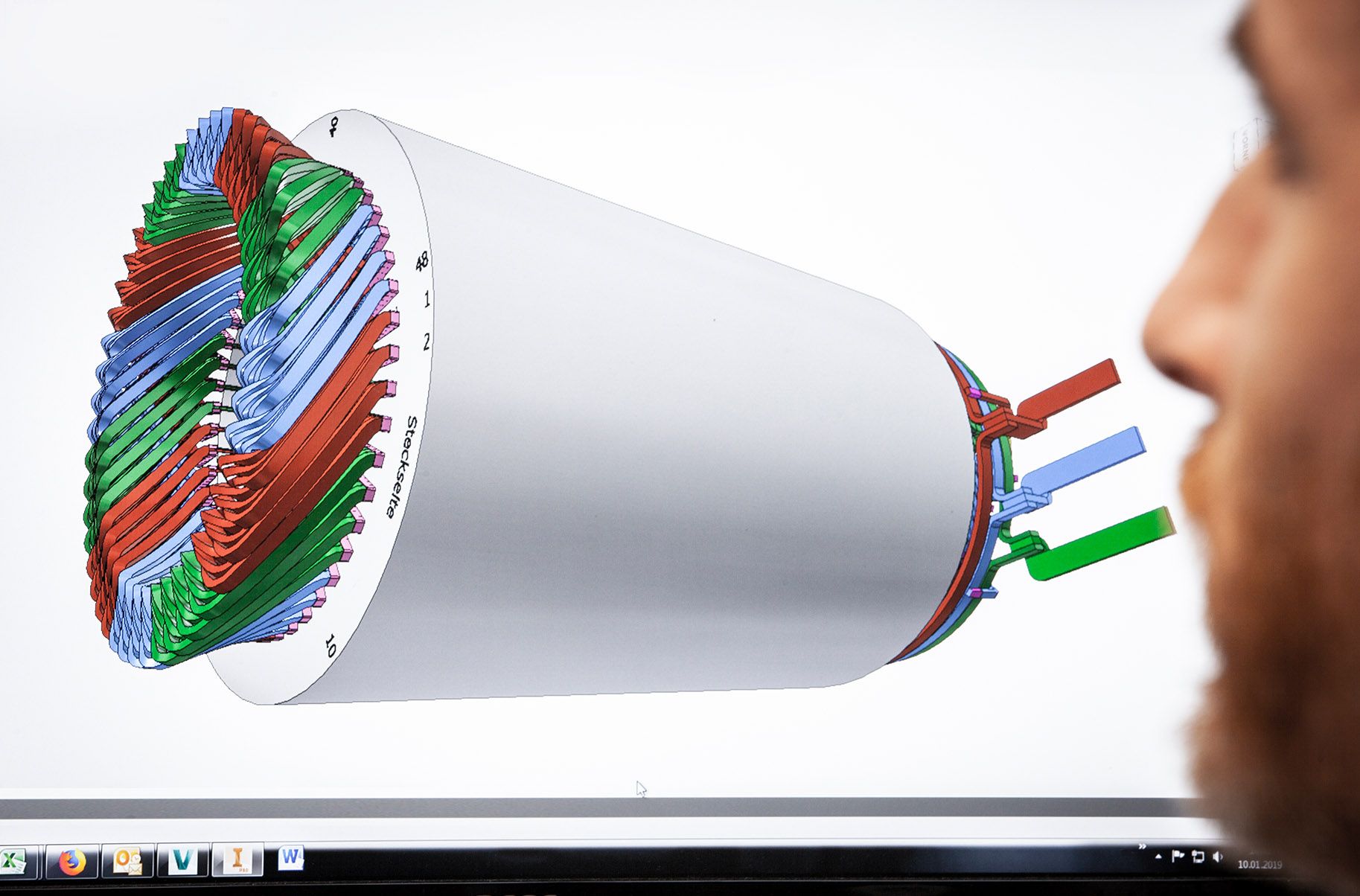

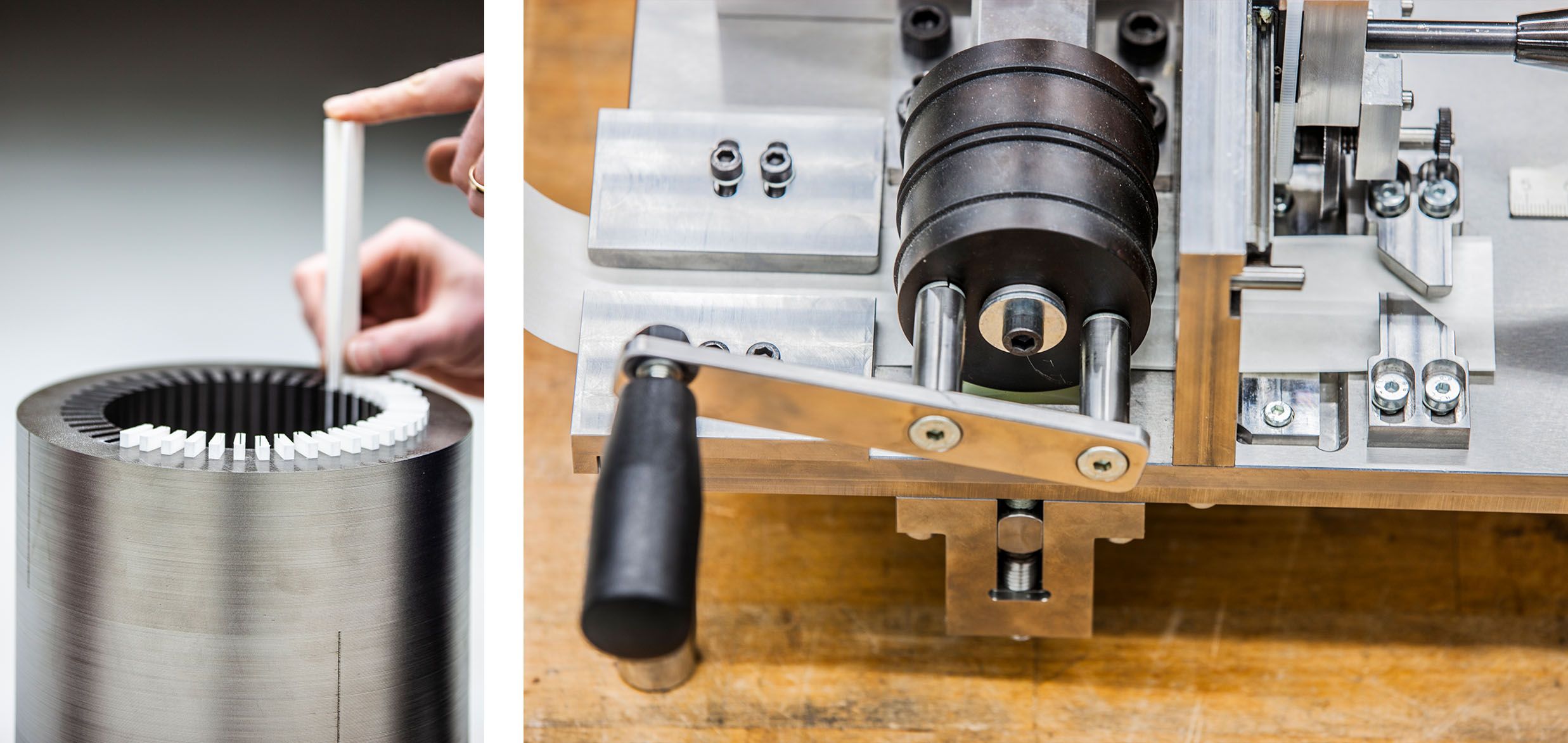

Hairpin technology is beginning to establish itself in electromobility. Unlike winding processes, in hairpin technology individual coil elements made of flat solid copper wire are inserted into the lamination stack and subsequently contacted with each other.

In the process chain for manufacturing a stator in hairpin technology, the core competencies of Röscher GmbH lie in the following process steps:

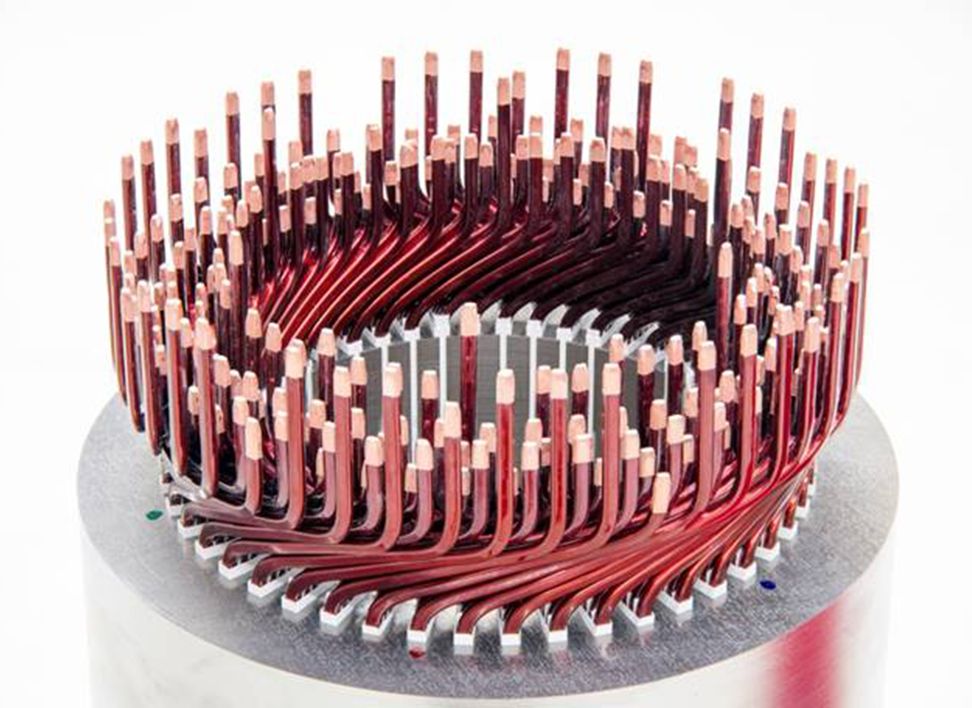

TWISTING

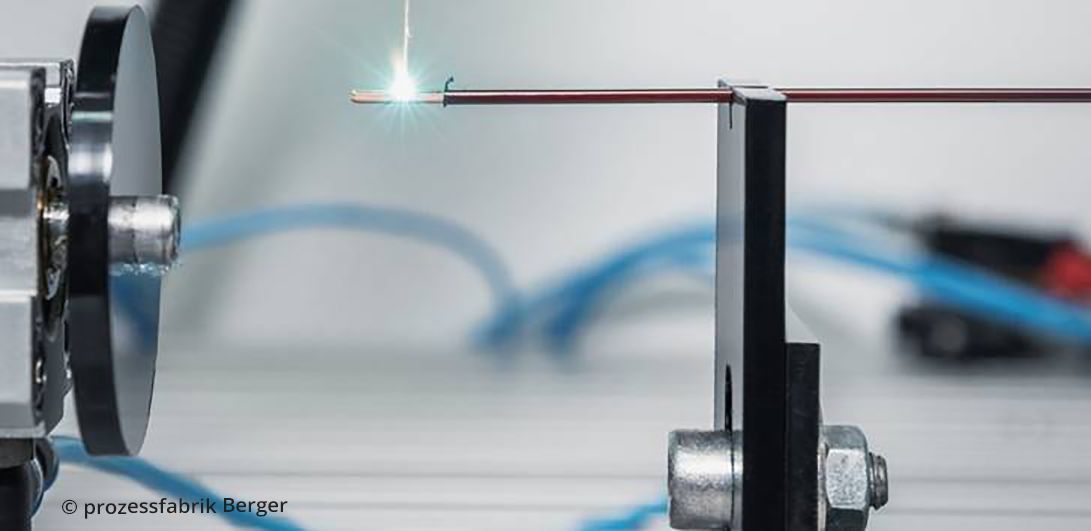

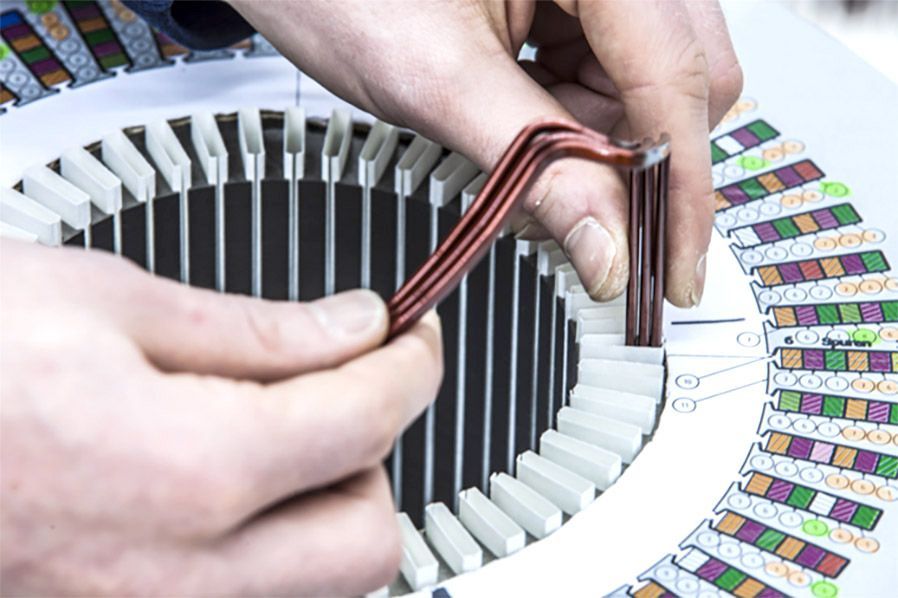

During twisting the wires of the stator are bent in opposite directions by a certain angle. They can then be welded together to form the desired electric coils.

The twisting tool must allow the complex bending without causing damage to the insulation layer.

Depending on the wire cross-section and the number of wires twisted at the same time, large forces occur that must be taken into account in the design of the system.

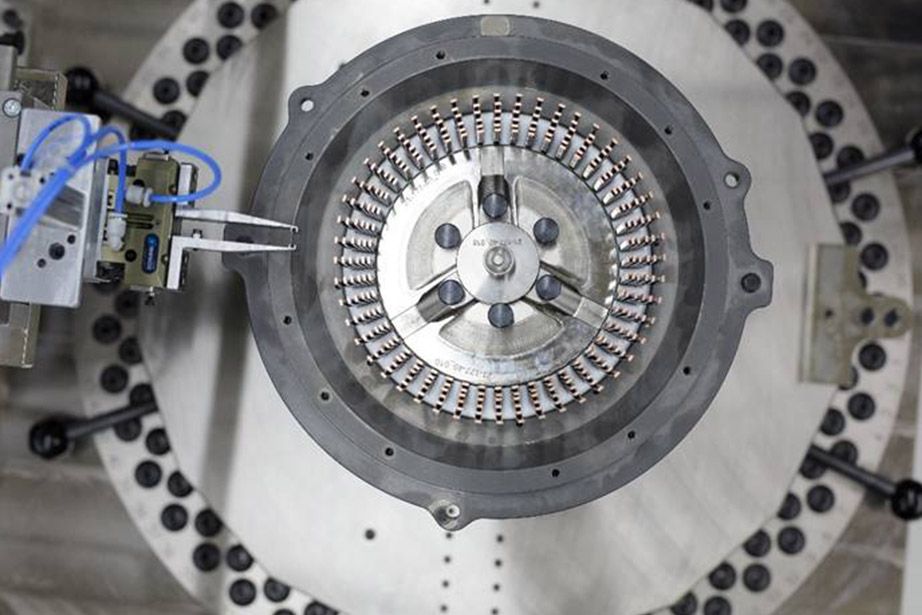

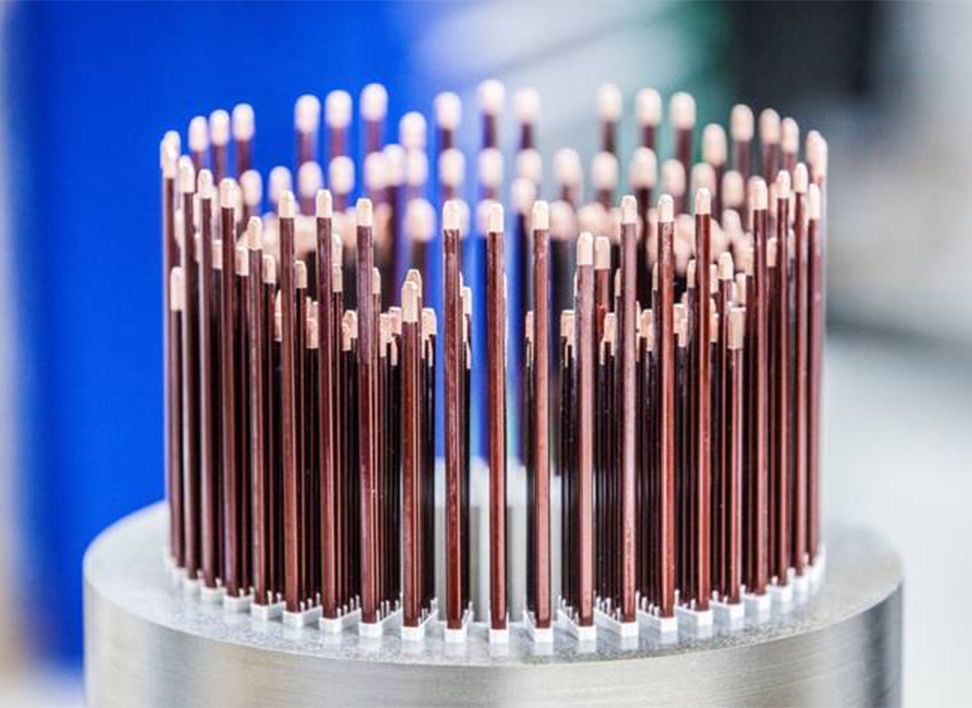

Stator before twisting – Stator after twisting

Do you want to manufacture a hairpin stator?

Then please consult us and our team to understand which of our solutions could support you.

SUCCESS STORIES

If you need a solution individually designed to your requirements, here are examples of how we have been able to help our customers.

In different industries, we have developed creative approaches with our team and built the desired machine or device.