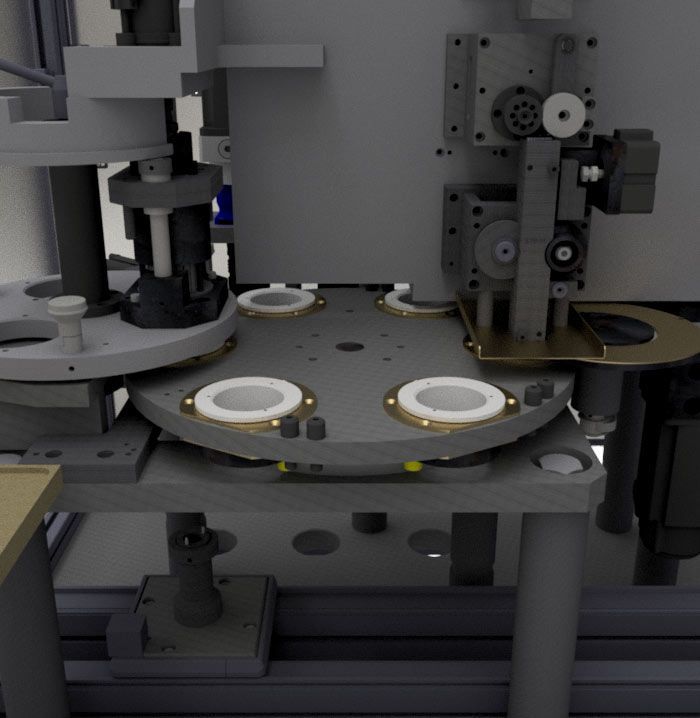

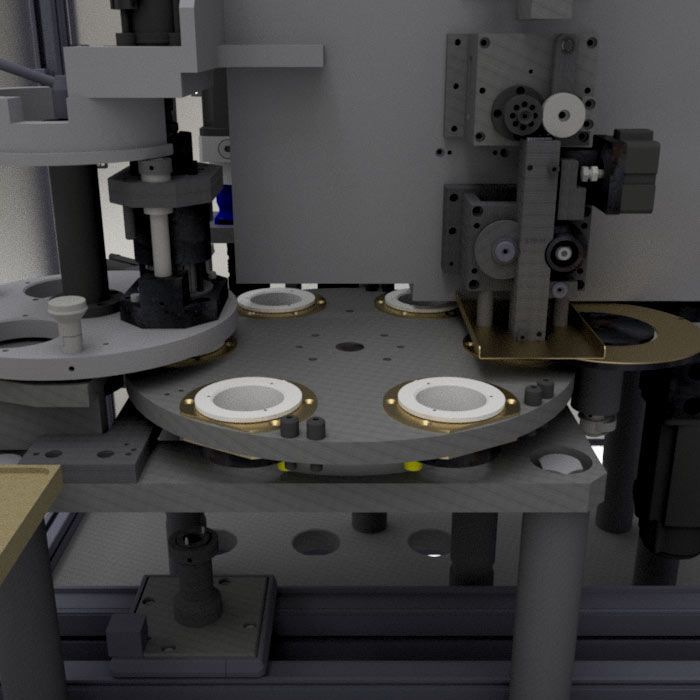

For petrol and diesel engines, the starter – a small electric motor – is responsible for starting the engine smoothly and quietly. For our customer SEG (formerly Bosch), Röscher GmbH has implemented a large number of fully automated systems for the series production of starters, for example for forming and inserting insulation paper into the lamination stack of the starter motor.

In this system, the insulation material provided on rolls is conveyed through a forming shaft via deflection rollers. It is rolled up to an oval shape with an overlap and inserted into an insertion master. Between the forming shaft and the insertion master, a rotating knife cuts off the insulation material. When all free slots of the insertion master are filled, the pre-formed insulation rolls are inserted into the waiting anchor with the help of a push-through basket.

In this system, a cycle time of around 10 seconds was achieved for an anchor with 28 slots.

That’s what our customer SEG says:

“Röscher GmbH’s solution is characterised by high reliability and safe achievement of the required tolerances in the lengths of the insulation paper. This ensures that our series production runs smoothly.”

Dr. Gero Heusler

Managing Director

Do you also have a challenge?

Then we will be happy to consult you with your request – please get in touch!

Phone: +49 30 53 89 85 56

E-Mail: g.heusler@roescher-gmbh.de